Horizontal Jackshaft

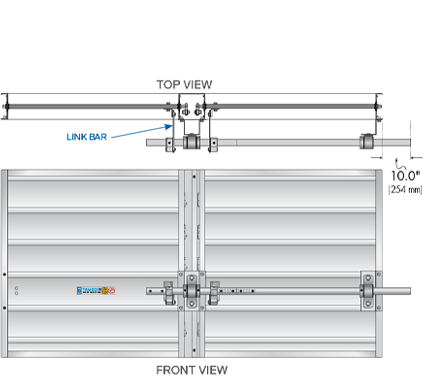

Multiple Section Horizontal Jackshaft for use with control dampers

Horizontal jackshafts are required whenever 30 ft² (2.79 m²) of damper surface area or more are to be actuated from any one motor location. They are also used if you wish to connect three (3) horizontal damper sections, even if the total surface area is less than 30 ft².

Jackshafts can be mounted so as to drive a two (2), three (3), or four (4) section wide damper from either the left or right side. (Right side shown here.)

Optional motor crankarm can be ordered as a separate part.

Jackshafts are mounted directly over the drive blade in order to minimize the length of the link bar. The shortness and thickness of the link bar prevents flexing and adds to positive control.

RECOMMENDATION:

Do not change the factory placement of blade crank arms along the 1” (25.4 mm)

diameter shaft within the bridge bracket assembly, as these are optimally aligned

for connection to the U-bolts on the damper blades.

- Features

- Documents

STANDARD HORIZONTAL JACKSHAFT:

- For use with Series 1000, 1500, 9000, and 9000 BF control dampers

- Bridge brackets and side brackets are mill finish extruded aluminum.

- 1” (25.4 mm) I.D. diameter bearings are high-strength, abrasion and impact resistant thermoplastic polyamide.

- Bearing housings are mill finish extruded aluminum.

- Blade clips are mill finish extruded aluminum. They are mounted directly to U-bolts and secured to drive blade.

- Shaft is 1″ (25.4 mm) diameter anodized extruded aluminum rod.

- Blade crankarms, locking collars, and link bars are mill finish extruded aluminum.

- All non-aluminum parts are zinc-plated steel.

- If jackshafts are required, all standard dampers and those with the SC or ECT Options are supplied with standard horizontal jackshafts. If Salt Water Resistance horizontal jackshafts are desired instead, this must be specified at the time of order.

SALT WATER RESISTANCE OPTION HORIZONTAL JACKSHAFT:

- For use with Series 1000, 1500, and 9000, 9000 BF control dampers with SW – Salt Water Resistance or MR – Moisture Resistance options

- Bridge brackets and side brackets are anodized extruded aluminum.

- 1” (25.4 mm) I.D. diameter bearings are high-strength, abrasion and impact resistant thermoplastic polyamide.

- Bearing housings are anodized extruded aluminum.

- Blade clips are anodized extruded aluminum. They are mounted directly to U-bolts and secured to drive blade.

- Shaft is 1″ (25.4 mm) diameter anodized extruded aluminum rod.

- Blade crankarms, locking collars, and link bars are anodized extruded aluminum.

- All non-aluminum parts are stainless steel.

- If jackshafts are required, all dampers with the SW or MR options are supplied with Salt Water Resistance horizontal jackshafts. If standard horizontal jackshafts are desired instead, this must be specified at the time of order.

Notes:

- A maximum of four sections can be connected with a single horizontal jackshaft, as standard. If more than four horizontal sections are to be connected using a jackshaft, contact Tamco Customer Service.

Recommended Maintenance:

- Thermoplastic polyamide bearings are self-lubricating and do not require any maintenance. Do not use any lubricants, such as grease or silicone, on any part of a Tamco jackshft.

- Jackshaft should be cleaned at least once a year, or as needed depending upon the environmental conditions. This can be done with the use of compressed air to loosen and remove any accumulated dirt or dust. If this does not clean off all the dust material, you may use a domestic strength steam cleaner, ensuring that the loosened dirt and water droplets are completely blown out with compressed air.

Horizontal Jackshaft Specifications

Download PDF Document

Download PDF Document (French)

Horizontal Jackshaft Suggested Specifications

Download Microsoft Word Document

Download Microsoft Word Document (French)